- RFQ

- BOM

-

Contact Us

Tel: +86-0755-83501315

Email: sales@sic-components.com

- Chinese

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Test and Measurement Equipment ICs: The Core of Precision Instrumentation

In the realm of test and measurement (T&M), accuracy, speed, and reliability are paramount. Behind every oscilloscope, spectrum analyzer, multimeter, or data logger lies a suite of specialized integrated circuits (ICs) that form the technological backbone of these instruments. Test and measurement equipment ICs are engineered to convert, process, and analyze electrical signals with exceptional precision, enabling engineers, scientists, and technicians to capture and interpret data across industries ranging from telecommunications to aerospace. This article explores the key categories of these ICs, their critical roles, and their impact on modern measurement systems.

The Role of ICs in Test and Measurement Equipment

Test and measurement equipment serves to quantify physical phenomena—such as voltage, current, frequency, or temperature—by translating them into measurable electrical signals. ICs in these systems perform three fundamental functions:

Signal Conditioning: Amplifying weak signals, filtering noise, and converting signals into formats suitable for processing (e.g., analog-to-digital conversion).

Precision Measurement: Enabling accurate quantification of signal parameters (e.g., voltage levels, frequency, phase).

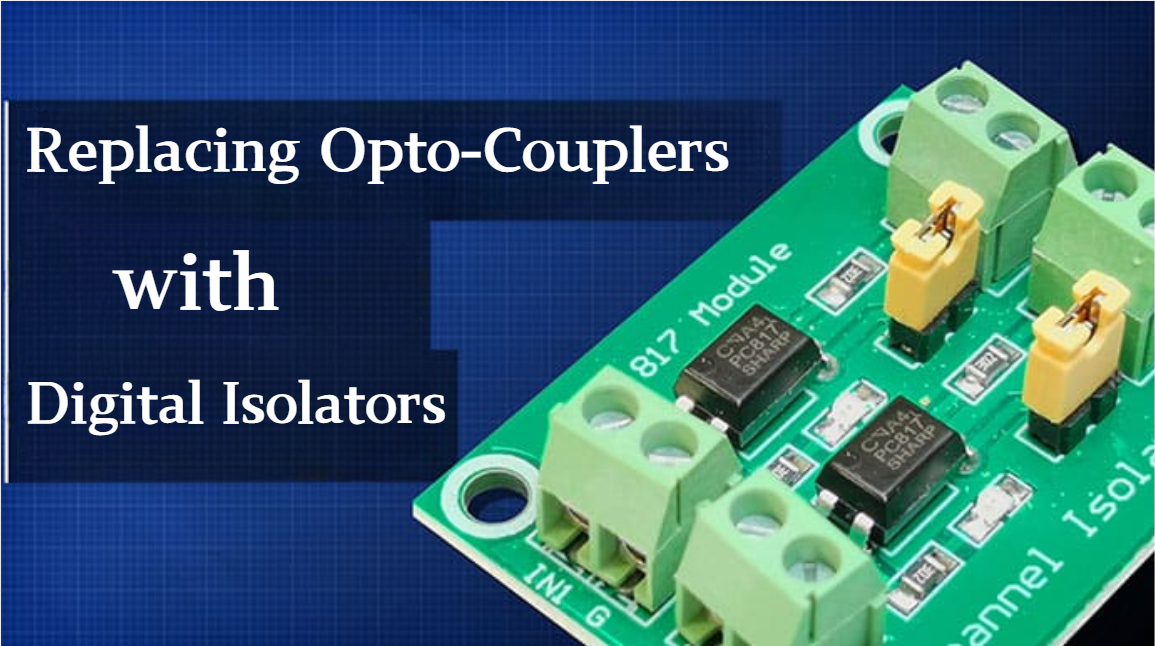

System Control: Managing data flow, synchronizing components, and facilitating communication between subsystems (e.g., between a sensor and a display).

Without specialized ICs, modern T&M equipment would lack the sensitivity to detect microvolt-level signals, the speed to analyze gigahertz-range frequencies, or the stability to maintain accuracy over time and environmental changes.

Key Categories of Test and Measurement Equipment ICs

1. Precision Analog-to-Digital Converters (ADCs)

ADCs are the bridge between the analog world (e.g., sensor outputs, RF signals) and digital processing systems. In T&M equipment, they must balance three critical parameters:

Resolution: The number of bits (e.g., 16-bit, 24-bit) determines the smallest signal change that can be detected. High-resolution ADCs (24-bit or higher) are essential for measuring faint signals, such as those from strain gauges or biomedical sensors.

Speed: The sampling rate (e.g., 1 MSPS to 10 GSPS) dictates how quickly signals can be digitized. Fast ADCs (≥1 GSPS) are used in oscilloscopes and spectrum analyzers to capture high-frequency signals like 5G waveforms or radar pulses.

Linear ity: The ability to convert analog signals to digital values without distortion. Low integral nonlinearity (INL) and differential nonlinearity (DNL) ensure measurements remain accurate across the ADC’s input range.

Example IC: Texas Instruments’ ADS1299 is a 24-bit, 8-channel ADC with a sampling rate of up to 32 kSPS, designed for high-precision applications like medical imaging and strain measurement. For high-speed needs, Analog Devices’ AD9208 offers 12-bit resolution at 1 GSPS, ideal for oscilloscopes analyzing fast digital signals.

2. Digital-to-Analog Converters (DACs)

DACs perform the inverse of ADCs, converting digital data into analog signals. In T&M equipment, they are used to generate reference signals, calibrate sensors, or simulate waveforms (e.g., in function generators). Key specifications include:

Settling Time: The time required for the output to stabilize after a digital input change, critical for generating fast-rise-time pulses.

Spurious-Free Dynamic Range (SFDR): A measure of how clean the output signal is, with higher SFDR (e.g., >80 dBc) ensuring minimal distortion in RF or audio test signals.

Example IC: Analog Devices’ AD5791 is a 20-bit DAC with 1 µs settling time and low noise, used in precision calibration systems. For waveform generation, Texas Instruments’ DAC38J84 offers 16-bit resolution at 12 GSPS, enabling the creation of high-frequency RF signals for wireless testing.

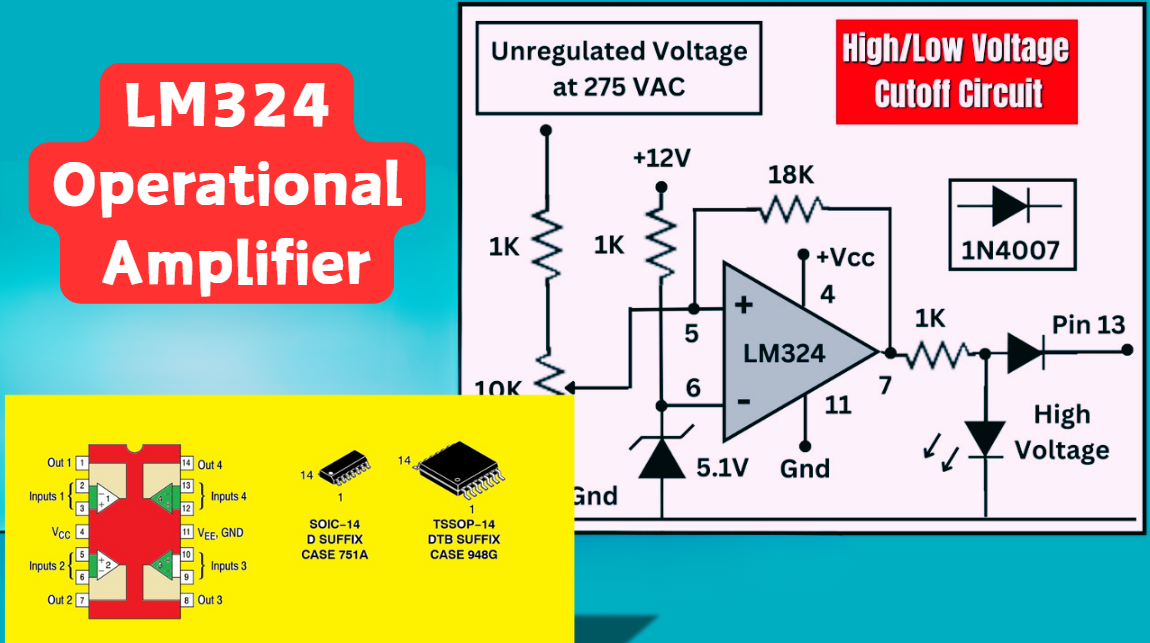

3. Precision Operational Amplifiers (Op-Amps)

Op-amps are workhorses in T&M equipment, used in signal conditioning circuits to amplify weak signals, buffer high-impedance sources, and implement filters. For test applications, they are characterized by:

Low Input Offset Voltage: Minimizing errors in DC or low-frequency measurements (e.g., <10 µV for precision multimeters).

High Common-Mode Rejection Ratio (CMRR): Rejecting noise from power lines or electromagnetic interference (e.g., >120 dB for ECG monitors or sensitive sensors).

Wide Bandwidth: Supporting high-frequency signal amplification (e.g., >1 GHz for RF test equipment).

Example IC: Analog Devices’ AD8676 is a precision op-amp with 1 µV input offset voltage and 130 dB CMRR, ideal for low-noise signal conditioning in multimeters. For high-speed applications, Texas Instruments’ OPA847 offers 1.8 GHz bandwidth, making it suitable for amplifying RF signals in spectrum analyzers.

4. Frequency Synthesizers and Phase-Locked Loops (PLLs)

Frequency synthesizers and PLLs generate stable, precise frequencies critical for instruments like spectrum analyzers, network analyzers, and signal generators. They enable:

Tunability: Generating frequencies across a wide range (e.g., from kHz to GHz) with fine resolution.

Stability: Maintaining frequency accuracy over temperature and time, often referenced to a high-precision crystal oscillator.

Example IC: Silicon Labs’ Si5351 is a low-cost frequency synthesizer with 8 output channels, generating frequencies up to 160 MHz—used in benchtop signal generators for hobbyists and educational labs. For high-performance RF testing, Analog Devices’ ADF4351 covers 35 MHz to 4.4 GHz with 0.01 Hz resolution, ideal for wireless communication testers.

5. Current-Sense Amplifiers

Current-sense amplifiers measure small voltage drops across shunt resistors to calculate current, a critical function in power supplies, battery testers, and energy meters. Key features include:

High Common-Mode Voltage Range: Withstanding voltages up to 100 V or more (e.g., in automotive or industrial power testing).

Low Offset and Drift: Ensuring accurate current measurements over temperature (e.g., <50 µV offset for precision power analyzers).

Example IC: Texas Instruments’ INA219 is a 36 V, bidirectional current-sense amplifier with an I²C interface, widely used in battery testers. For high-power applications, Maxim’s MAX40050 offers a 70 V common-mode range and 20 µV offset, suitable for industrial current measurement.

Trends Shaping Test and Measurement Equipment ICs

1. Higher Integration

Modern T&M ICs are increasingly integrating multiple functions into a single chip to reduce system size and complexity. For example, Analog Devices’ AD7768 is a 24-bit ADC with built-in programmable gain amplifiers (PGAs) and filters, eliminating the need for external signal conditioning components in data acquisition systems.

2. Increased Speed and Bandwidth

As wireless standards (e.g., 5G, 6G) and high-speed digital interfaces (e.g., PCIe 6.0, USB4) push signal frequencies into the tens of gigahertz, T&M ICs are evolving to match. ADCs and DACs with sampling rates exceeding 100 GSPS are now in development, enabling the analysis of ultra-wideband signals.

3. Low-Power Design

Portable and battery-powered T&M devices (e.g., handheld oscilloscopes, field sensors) demand ICs with minimal power consumption. ICs like Texas Instruments’ ADS1115 (a 16-bit ADC consuming <1 mW) enable long-lasting, portable measurement tools.

4. Digital Intelligence

Some T&M ICs now incorporate on-chip digital signal processing (DSP) or machine learning (ML) cores to enable real-time data analysis. For example, Maxim’s MAX77650 integrates a DSP with a 16-bit ADC, allowing it to filter noise and correct for sensor nonlinearity without external processing.

Conclusion

Test and measurement equipment ICs are the unsung heroes of precision instrumentation, enabling the accurate, reliable, and efficient measurement of electrical signals across countless applications. From the low-noise op-amps amplifying neural signals in medical devices to the high-speed ADCs capturing 5G waveforms in telecom labs, these ICs define the capabilities of modern T&M systems. As technology advances, the demand for ICs with higher speed, integration, and intelligence will only grow, driving innovation in industries that depend on precise measurement to push the boundaries of what is possible. For engineers designing test equipment, understanding these ICs—and selecting the right ones for the task—is key to building instruments that meet the rigorous demands of today’s technical landscape.

https://www.sic-com

Hot Products

View MoreRelated Blogs

2000+

Daily average RFQ Volume

30,000,000

Standard Product Unit

2800+

Worldwide Manufacturers

15,000 m2

In-stock Warehouse

Wishlist (0 Items)

Wishlist (0 Items)